In this March edition of our HUD-REAC newsletter, I will be discussing the deficiencies associated with your Fire Sprinkler System.

- For a single building property, this deficiency is a TEN POINT DEDUCTION

- Although HUD’s deficiency for Fire Sprinklers is “Missing Sprinkler Head,” the word ‘missing’ is equivalent to ‘damaged’ in the REAC Protocol.

- “Painted over” (also known as Loaded) means anything on the sprinkler head assembly that should not be there including drywall compound, caulk, adhesive, excessive dust and dirt, rust and corrosion.

HUD’s Defect Definition:

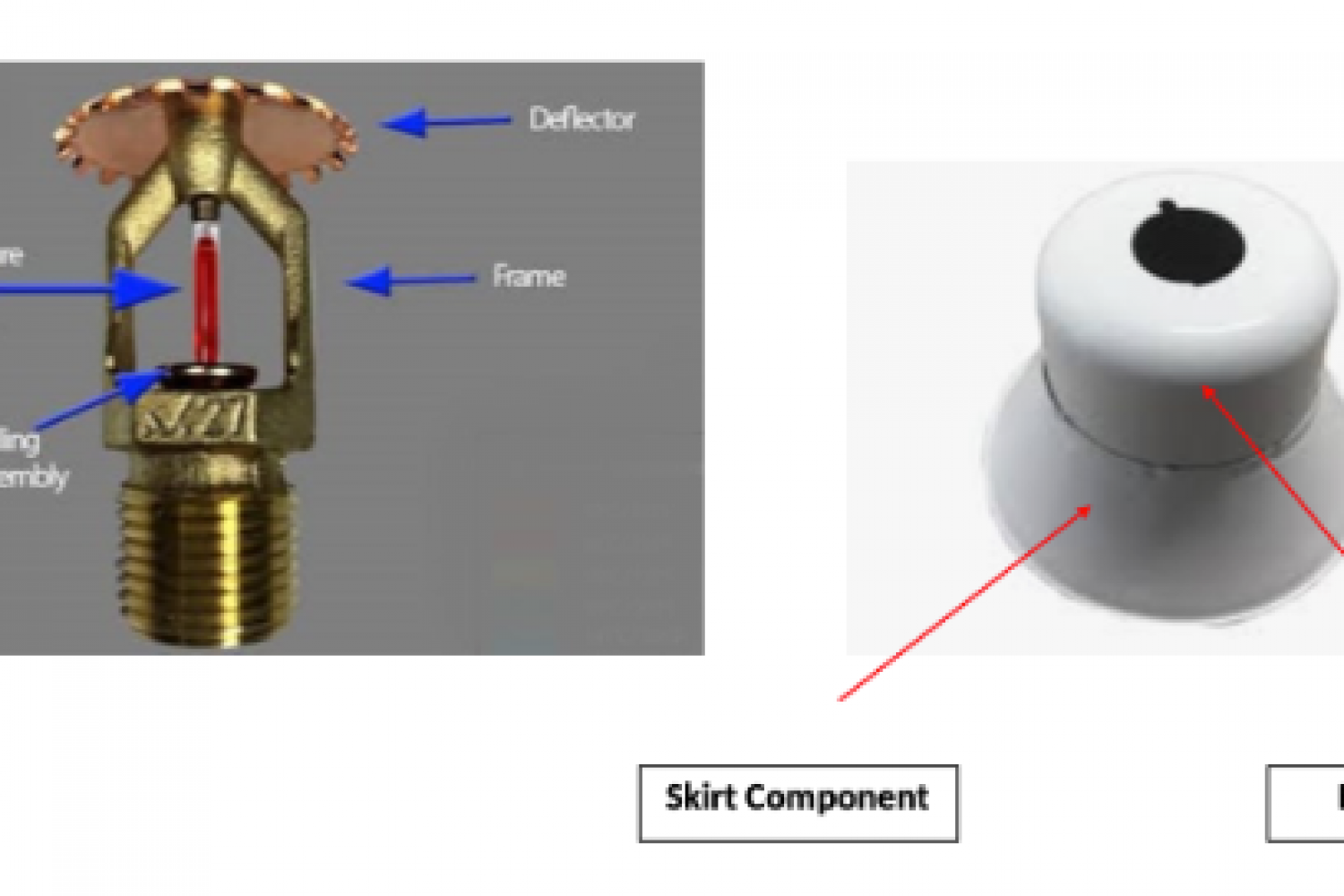

- You see that a sprinkler head OR its components are either missing, visibly disabled, painted over, blocked or capped.

- Components include test plugs, drains and test fittings

If paint or other obstruction is observed on the sprinkler head, a deficiency will be recorded - Paint on an escutcheon plate should NOT be recorded as a deficiency

- If the escutcheon plate or any other components are missing or damaged – it will be recorded as a deficiency

- The hole in the ceiling the escutcheon does not cover is a L1 hole – NOT a sprinkler system deficiency!

- The sprinkler head on the left is a “Factory white” sprinkler head – it came from the manufacturer this way and there is no deficiency.

- The sprinkler head on the right is the exact same head…but completely painted on-site.

- Nearly every code (IFC, IBC, IRC, NFPA 1, IECC) and standard (NFPA 13 and NFPA 25) has language that prohibits a painted or otherwise loaded sprinkler head.

Why?

- Paint, dust or other materials can coat the link, valve, deflector or bulb and delay or prevent operation!

You cannot repair a painted/loaded sprinkler head. It must be replaced.

NFPA 25

5.2.1.1.1 – Any sprinkler that shows signs of any of the following shall be replaced:

- Leakage

- Corrosion detrimental to sprinkler performance

- Physical damage

- Loss of fluid in the glass bulb heat-responsive element

- Loading detrimental to sprinkler performance

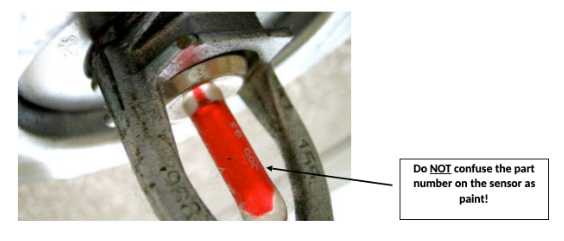

- Paint other than that applied by the sprinkler manufacturer

HUD will not accept ONE SPECK of paint anywhere on the sprinkler head assembly.

- NFPA 25 requires an annual visual inspection “from the floor level” of both sprinkler heads and the pipe and fittings they are attached to. Your sprinkler inspector absolutely must have a flashlight to perform this task.

- CHECK YOUR INSPECTION REPORT for the section that states something like, “Are sprinkler heads free of damage, obstruction, paint, and dirt?” If it is marked No or N/A, you will need to have a conversation with your sprinkler company.

- If this is not on the report, get it in writing that all the heads were visually inspected and whether deficiencies were observed or not!

- Make sure all your paint contractors cover the sprinkler heads prior to painting. Do not accept the excuse, “But I’m careful!” unless the painters are willing to pay the sprinkler replacement costs and take on the liability if the painted head does not go off in the event of a fire.

- Pay particular attention to obscure places (like closets) – those are where we find most of the painted/loaded sprinkler heads!

- If management/maintenance are unable to accompany the sprinkler inspector, conduct your own visual inspection (with a flashlight!) prior to any REAC inspection.

- CHECK YOUR INSPECTION REPORT for the section that states something like, “Are sprinkler heads free of damage, obstruction, paint, and dirt?” If it is marked No or N/A, you will need to have a conversation with your sprinkler company.

- Additionally, your 5-year inspection report should NEVER have an “N/A” under “Obstruction Investigation” as it is required by the NFPA 25 – this is the internal pipe inspection for the condition of the pipe, water quality, and any obstructions.