In this August edition of our HUD-REAC newsletter, I’d like to discuss breaker panels!

-

- A breaker shuts off a component (like a kitchen stove or outlets) – whereas a disconnect will shut off an area or system (like a service disconnect at the meter that shuts off the entire unit or an HVAC disconnect).

- If the breaker panel is secured (locked, screwed shut) at the time of inspection – you MUST make the panel accessible to the inspector.

- The fact it’s secured is NOT a defect!

- If you refuse to open the panel, it can be recorded as Level 3 – Blocked Access

- Foreign materials (caulk, foam, screws) in the panel are a defect. The only acceptable materials allowed are UL rated such as blanks for breaker ports.

-

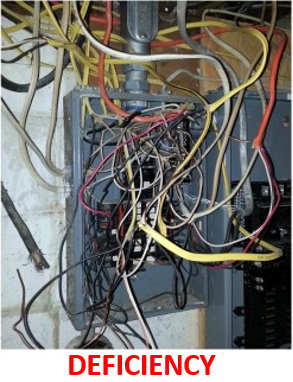

- There are many defects that inspectors look for inside the breaker panels:

- Burnt Breakers

- Evidence of Leaks/Corrosion (Rust)

- Missing Breakers/Fuses

- Use a blank to fill the gap or

- A dummy breaker (not connected to anything)

- Missing Covers (internal cover….not the external cover) – wires have to be exposed as a result of the missing cover!

- Openings over ¼ inch (includes missing knockouts under or on the side of the panel)

- ¼ inch is larger than you may think – stack 4 pennies and that is exactly ¼ inch.

- Do NOT put the pennies in an electric panel!

- If your breaker panel is abandoned, all capped wires (abandoned or otherwise), bare wires, un-insulated connectors, or open terminal connections visible in an open junction box/pass-through MUST be properly enclosed in a SECURED junction box

- There are many defects that inspectors look for inside the breaker panels: